FAQ

Common questions and answers regarding Designs of Distinction® components for Kitchen, Bath, & Home.

Please note: Our FAQ page is under construction! Check back regularly for FAQ updates.

Please click on the links below to jump to specific FAQ sections, or download this page as a PDF.

Click on the links to jump to specific FAQ sections within this page:

Click on the links to download a PDF copy of FAQ sections:

General FAQ

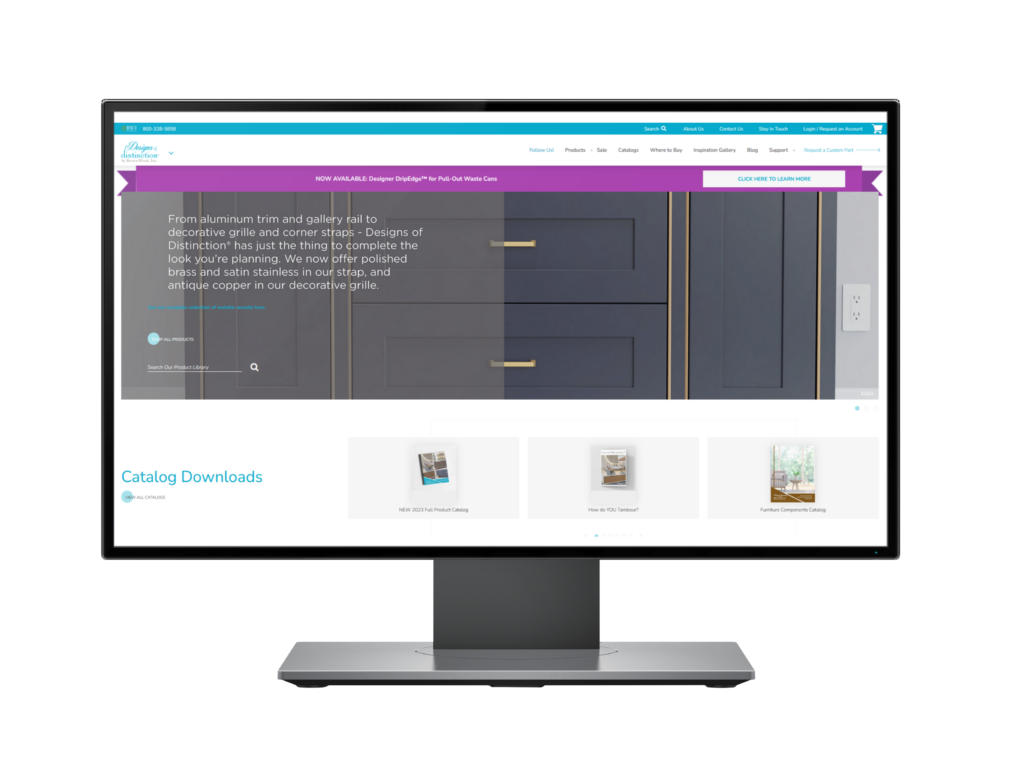

Designs of Distinction is a premier line of decorative wood and metal elements for kitchen, bath, and home, proudly serving other businesses since 1998. Made in America, of superior quality and first-class materials, Designs of Distinction’s product line has grown from 100 elements to more than 5000 components, all in stock and available for immediate shipment. Give us a call today at 800-328-5858.

Who do you sell to? Designs of Distinction sells to trade customers only, including businesses such as cabinet manufacturers, furniture makers, woodworkers and interior designers.

I don’t have a business and I want to purchase for personal use. How do I buy your products? Our products can be purchased through our trusted online distributor partners. That list can be found here.

I have a business. How do I request an account? An account can be requested here. We reply to requests within 1-2 business days.

What species of wood do you offer? Most products are available in American Hard Maple, Red Oak, Alder and Cherry. Some of our products are available in Hickory, Ash, Quartersawn Red Oak, White Oak, Walnut and Paint Grade. Exotic species are also available on a custom basis.

I have a part that I would like replicated. Can you do this? Yes! We specialize in small and large quantity custom. Request a quote here.

How do I see my trade pricing? Either request an account here or login to your account here. Once logged into your account, your trade pricing will show for all products.

How do I find out about new products? Subscribe to our email list and follow us on Instagram and on other Social Media to see our newest products and in-use images!

General FAQ – Web Order Processing

Orders can be submitted via phone, email, fax, or on our website.

To submit orders through phone, email, or fax, see contact information below:

- Call us at 800-328-5858

- Fax us at 815-425-8777

- Email us at orders@brownwoodinc.com

This section will focus on online order processing.

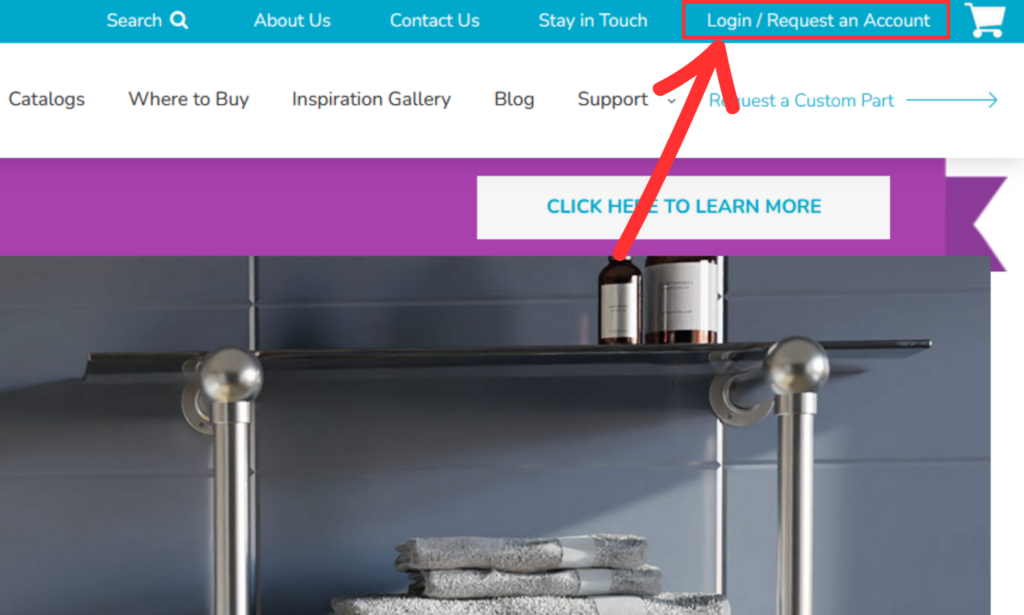

To see your pricing and place orders online, you’ll need to be logged in to your web account. If you do not have a web account with us, please request an account.

I’ve placed orders with you before, so I know I have an account. Why can’t I login to your website with my account information? If you’ve setup an account with us via phone, email, etc., you will still need to setup a web account. We do not automatically set up web accounts. To set up your web account, please request an account here. You will need:

- Your first & last name

- Your contact information (phone, email, fax if needed)

- Company name

- Company address

- Business verification (resale tax ID, EIN, or company website)

After you enter your information, you will need to agree to the statement “I understand that accounts are only for resellers and are not offered to end users.” Designs of Distinction only sells business-to-business. Homeowners, DIYers, and consumers can purchase our products through our online distributors.

We receive a notification when accounts are requested and generally approve requests within 24-48 hours. Once your request is approved, you will receive a link to set up your online profile including your password, shipping address, contact info, and more. You can then see your price and place orders online.

See below for a step-by-step process to place orders on our website.

Step #1: Login

Login to your account using your account number (begins with 01-) and password.

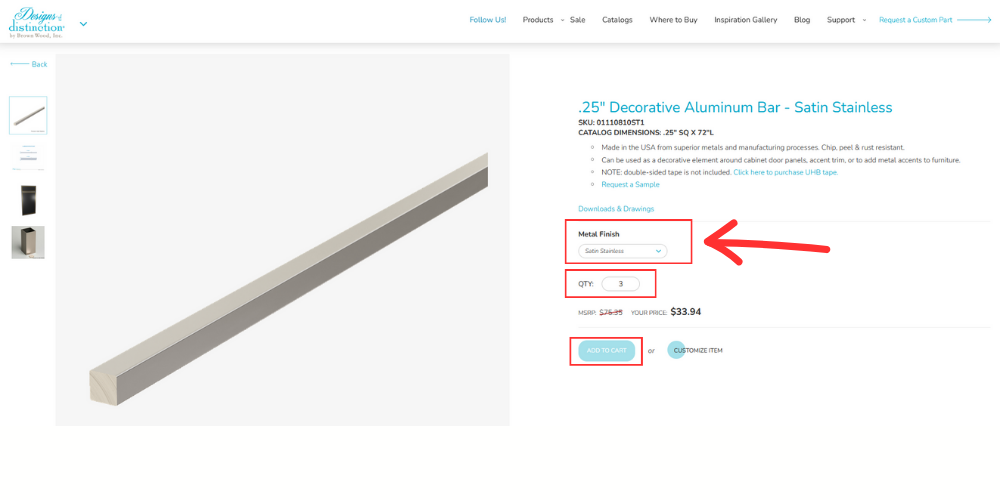

Step #2: Shop & Add to Cart

Shop around! Select your finish/size/species/etc., adjust quantity if needed, and add to cart. Adding products to your cart will not automatically take you to the cart page, but quantity will show in the cart icon.

You will NOT be able to add products to your cart without first selecting species, finish, size, etc. Select your desired options from the drop down boxes.

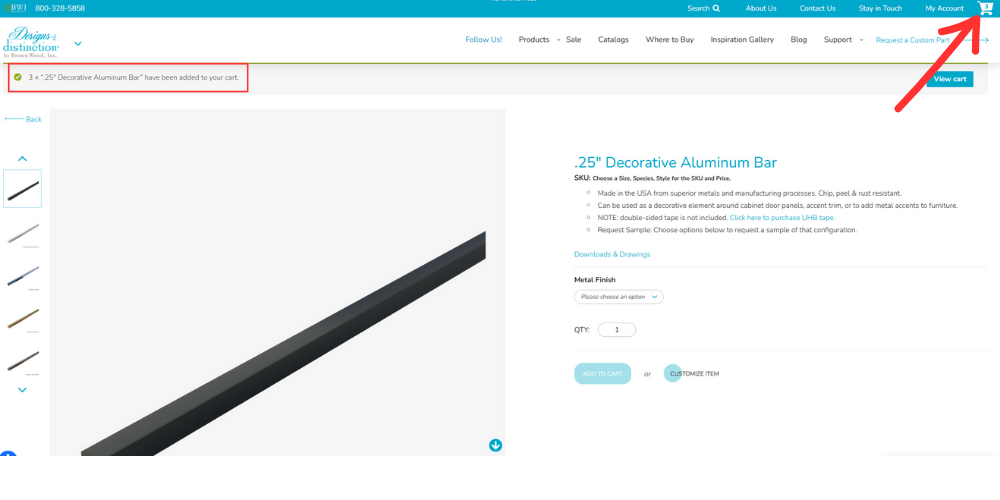

You will know when the product has been successfully added to your cart when you receive this message and the quantity shows in the cart icon:

Step #3: Access Cart & Begin Checkout

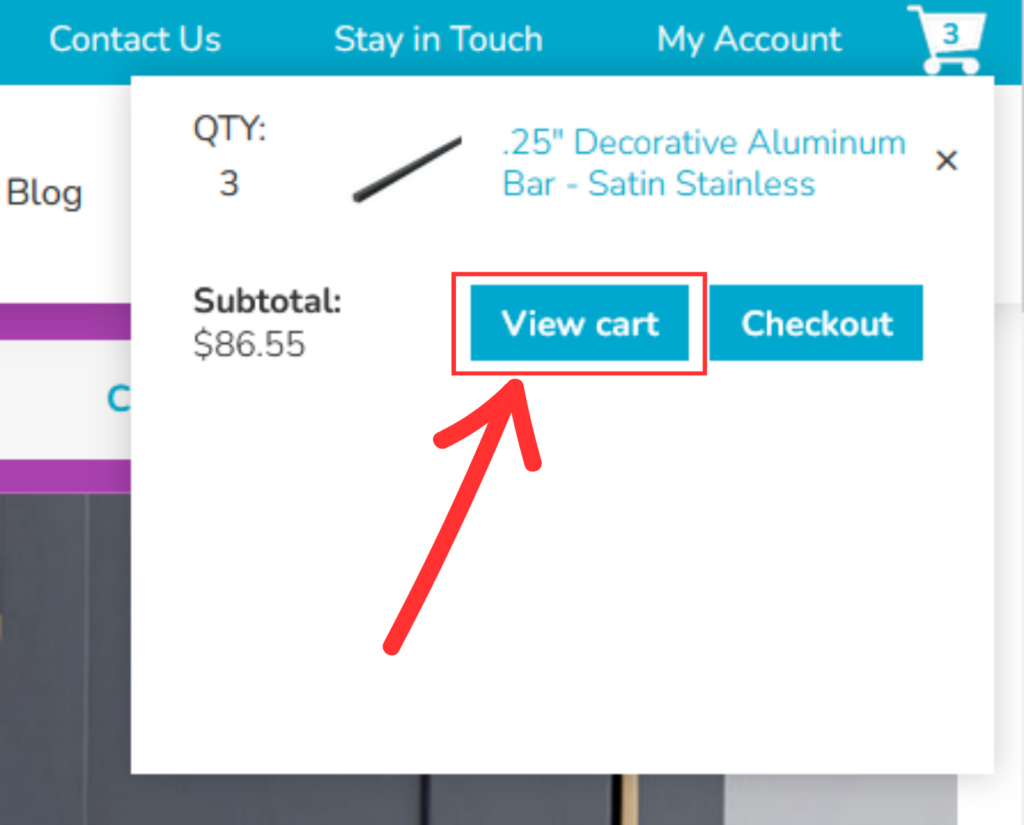

After you’ve finished adding products to your cart, click on the cart icon and press “view cart” (shown below):

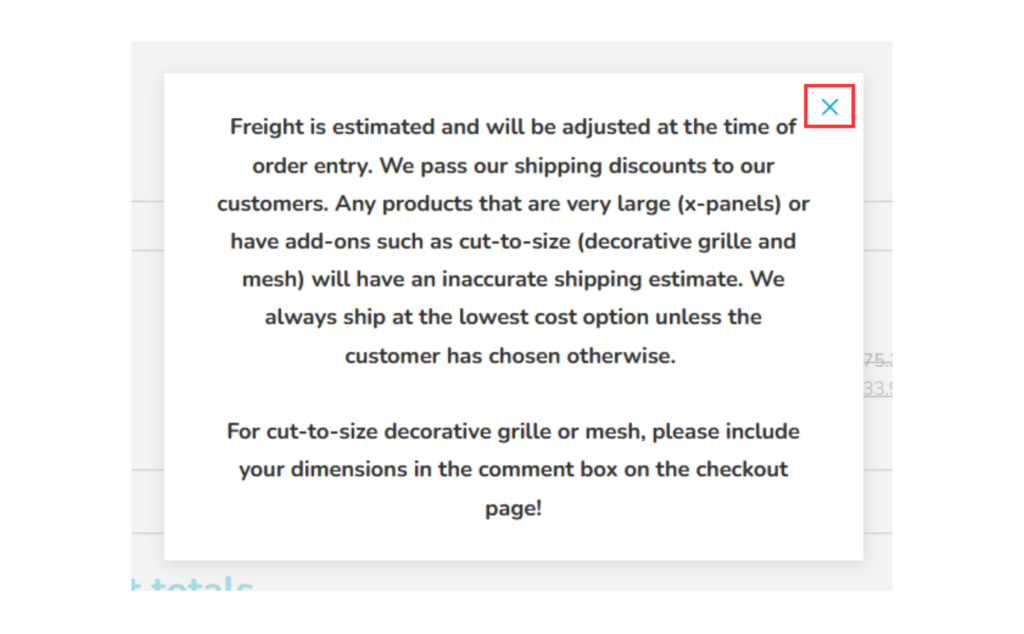

Step #4: Read, confirm, and close out of pop-up window regarding estimated shipment fees.

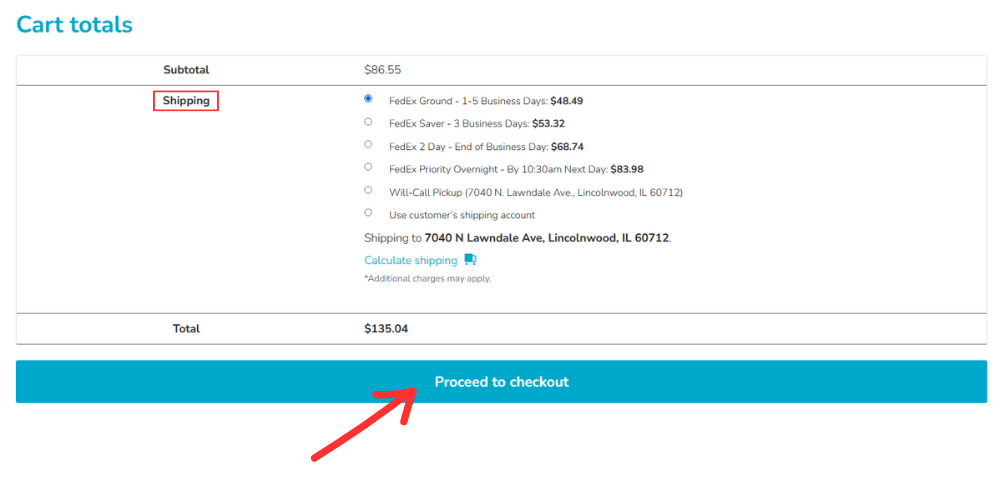

Step #5: Choose shipping method & proceed to checkout.

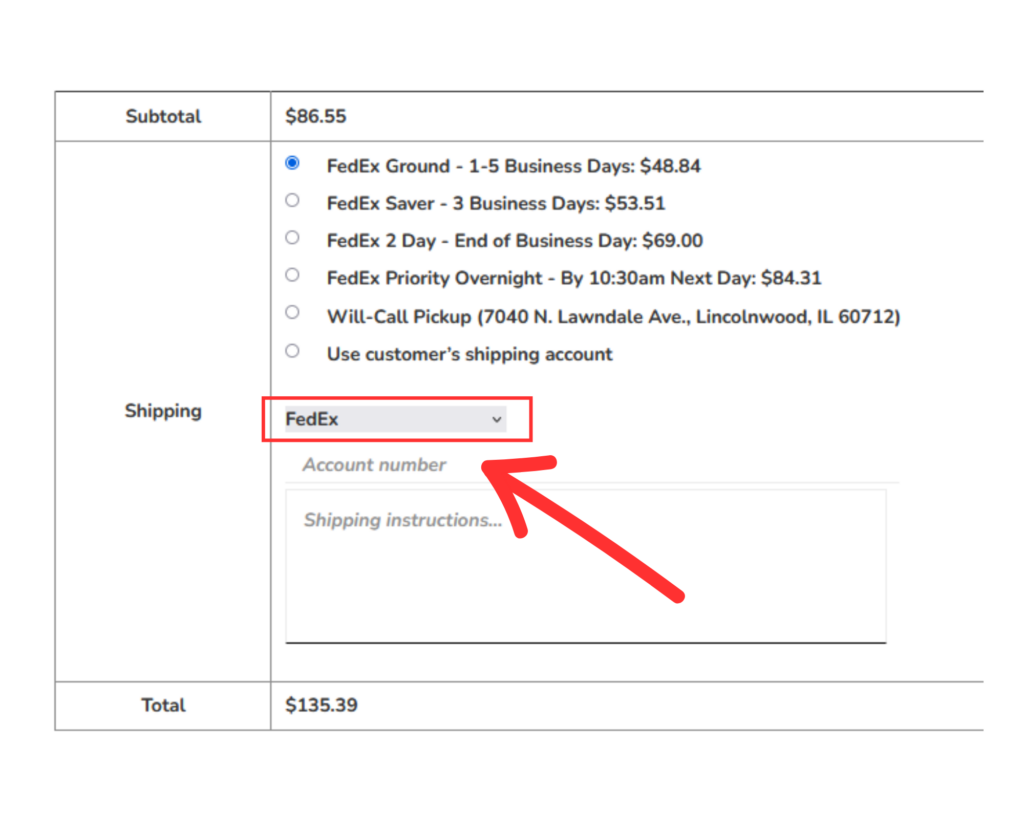

If you have a shipping account you’d like to use, select “Use customer’s shipping account.” Otherwise, select a method of shipping. You must choose a shipping option to proceed. If you’d like us to your shipping account, you will be able to enter your shipping account information later.

If you do not see shipping options, you will need to update your web account profile with a shipping address.

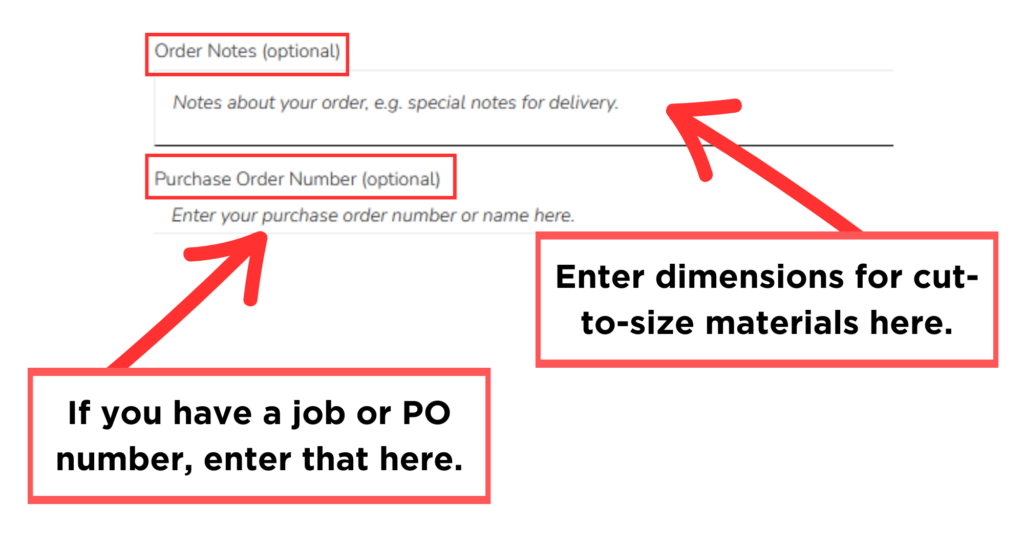

Step #6: Continue through checkout by entering your billing and shipping details. On the shipping details page, you can enter order notes and PO number. If you are ordering cut-to-size materials, the “Order Notes” section is where you would enter your panel dimensions.

Step #7: Proceed to order & shipping options. If you have a shipping account you’d like us to use, this is where you can enter that information.

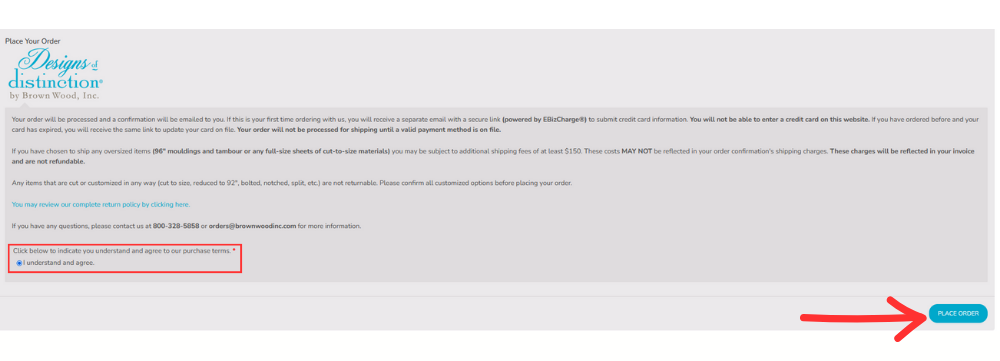

Step #8: Proceed to payment page. Review and agree to the purchase terms and click “PLACE ORDER.”

NOTE: You will NOT be charged at the time your order is placed. We will charge your card or invoice you when we ship the product. See here for payment information and options. More info coming soon!

I’ve placed my order online. Now what? Once you place your order online, we receive an email with your order details. We’ll enter your order in our system. Once your order is entered in our system, you will receive an email order confirmation with your order details. Review your order confirmation carefully. If you see errors in your order confirmation, contact us ASAP. Review your confirmation for:

- Quantity ordered

- Shipping/billing address

- Your PO/job number

- Shipping account details (especially if you want us to ship on your account.

If the product you ordered is on back order, we will indicate the estimated lead time on your order confirmation. Additionally, we may reach out to see if you’d like us to ship a partial order, or ship complete when all components are in stock. Emails regarding your order details are sent from orders@brownwoodinc.com.

After I place an order online, how long until it ships? If your products are in stock, we ship orders within 1-3 business days. If you placed an order for cut-to-size materials, orders are shipped within 7 business days.

Why can’t I see the tracking information online? Currently, our website and internal systems are not integrated. Tracking information is available in our internal system but does not translate to our website. If you are looking for a tracking number, please call, email, or live chat us. We hope to integrate our systems soon.

I’ve followed the steps and I’m still having issues placing my order online. Why? Online order troubleshooting coming soon! In the meantime, you can call, email, or live chat us with any online ordering questions.

Product FAQ – Tambour

Flexible & Solid Tambour Panels

Made in America from American hardwoods, Tambour ships ready to finish in paint or stain. Flexible Tambour has a thin backer, allowing Tambour to be used as a wrap and bend around curves. Solid Tambour makes an ideal insert for cabinet doors, or as full panels on cabinetry and furniture.

Where can I find Tambour in your 2023 Product Catalog? Tambour profiles are on pages 7-10 of the 2023 Product Catalog. Additionally, you can view the specific Tambour catalog pages here.

I need to show my client Tambour styles and species. Do you have sample kits? Yes! We have a Tambour Sample Kit. Contact us via live chat, email orders@brownwoodinc.com, or call us at 800-328-5858 to request a custom Tambour sample set.

How many square feet is each panel?

- 12″ x 96″ Panels = 8 SQ feet

- 12″ x 48″ Panels = 4 SQ feet

- 24″ x 48″ Panels = 8 SQ feet

How do I determine how many square feet of Tambour I need? Multiply the width in inches (10 ft. or 120 inches) by the length/height in inches (4 ft. or 48 inches), then divide by 144. (120 * 48 = 5760)/144=40 Sq. Ft. For this example, you could buy (5) 96” panels and cut them in half or buy (10) 48” panels.

What sizes do you carry for flexible Tambour panels? Flexible Tambour panels are available as 12″W X 48″L or 12″W x 96″L. Some thinner profiles are offered in 24″W x 48″L. Panels offered in 24″W x 48″L include styles 100, 102, 107, 110, 302, 402, and 403.

What species are available for flexible Tambour panels? We stock flexible Tambour panels in Hard Maple, Red Oak, White Oak, Walnut, or Paint Grade Poplar. If you plan to stain, we suggest White Oak, Red Oak, or Walnut. For paint, we suggest Hard Maple or Paint Grade Poplar.

Why aren’t 24″W panels offered in 96″L for all profiles? Panels over 24″W x 48″L are extremely heavy and difficult to move and ship.

What is the purpose of a 24″W flexible panel, why not just offer the 12″W panels? The 24″ x 48″ panels were specifically designed for cabinet and furniture manufacturers who want to adhere the Tambour to a backer. The majority of door panels are under 24″W and 48″L, so this meets a niche market need.

How do you attach the flexible panels to walls or furniture? Any standard construction glue, pin nails, or finishing nails.

How can I customize the flexible Tambour panels?

- Species: We can do any species but a minimum run of 48 SQ feet is required.

- Style: We can typically create a new tool, minimum tool charge is $300 PLUS minimum run of 48 SQ feet.

- Length: We can create Tambour up to 10′ long but require a minimum run of 48 SQ feet regardless of style. Oversized charges apply.

- Lead time: Typically, 4 weeks for new tools and an additional 4-6 weeks for manufacturing. Please note that Tambour is a very popular item and lead times may be longer than usual.

What sizes do you carry for solid Tambour panels? Solid Tambour panels are 24″W x 46″L.

What species are available for solid Tambour panels? We stock solid Tambour panels in Hard Maple, White Oak, Red Oak, Walnut, Cherry, Alder, and Paint Grade Brown Maple. If you plan to stain, we suggest White Oak, Red Oak, Walnut, or Cherry. If you plan to paint, we suggest Hard Maple, Paint Grade Maple, or Alder.

What is the difference between a solid panel and flexible Tambour panel? Solid panels are made from laminated panels and CNC’d as a single sheet. They are not flexible. Flexible panels are moulded pieces that get glued to a flexible cloth or paper backer.

Why are solid Tambour panels 24″ x 46″? Solid Tambour panels were designed specifically for the cabinet manufacturing market. This dimension fits on a pallet and/or easily ships FedEx/UPS. Like our 24″ x 48″ flexible panels, they fit the dimensional needs of cabinet manufacturers.

What are solid panels used for? Depending on the thickness, solid panels can be used as panel skins, panel inserts, or solid doors.

How much can I customize solid Tambour panels?

- Species: We can do any species but a minimum run of 5 full sheets (24″ x 46″) is required.

- Style: We can typically create a new tool; minimum tool charge is $650 PLUS minimum run of 5 full sheets.

- Custom sizes: We can CNC sheets up to 4′ x 8′ but caution that warpage can be an issue depending on profile/thickness; 5 full sheet minimum applies.

- Lead time: Typically, 6 weeks for new tools and an additional 2 weeks for manufacturing. Please note that Tambour is a very popular item and lead times may be longer than usual.

How do you attach the solid panels to walls or furniture? Any standard construction glue, pin nails, or finishing nails.

Have a question about Tambour that isn’t answered above? Contact us through live chat at the bottom right of your screen, or fill out this form. We invite your feedback!

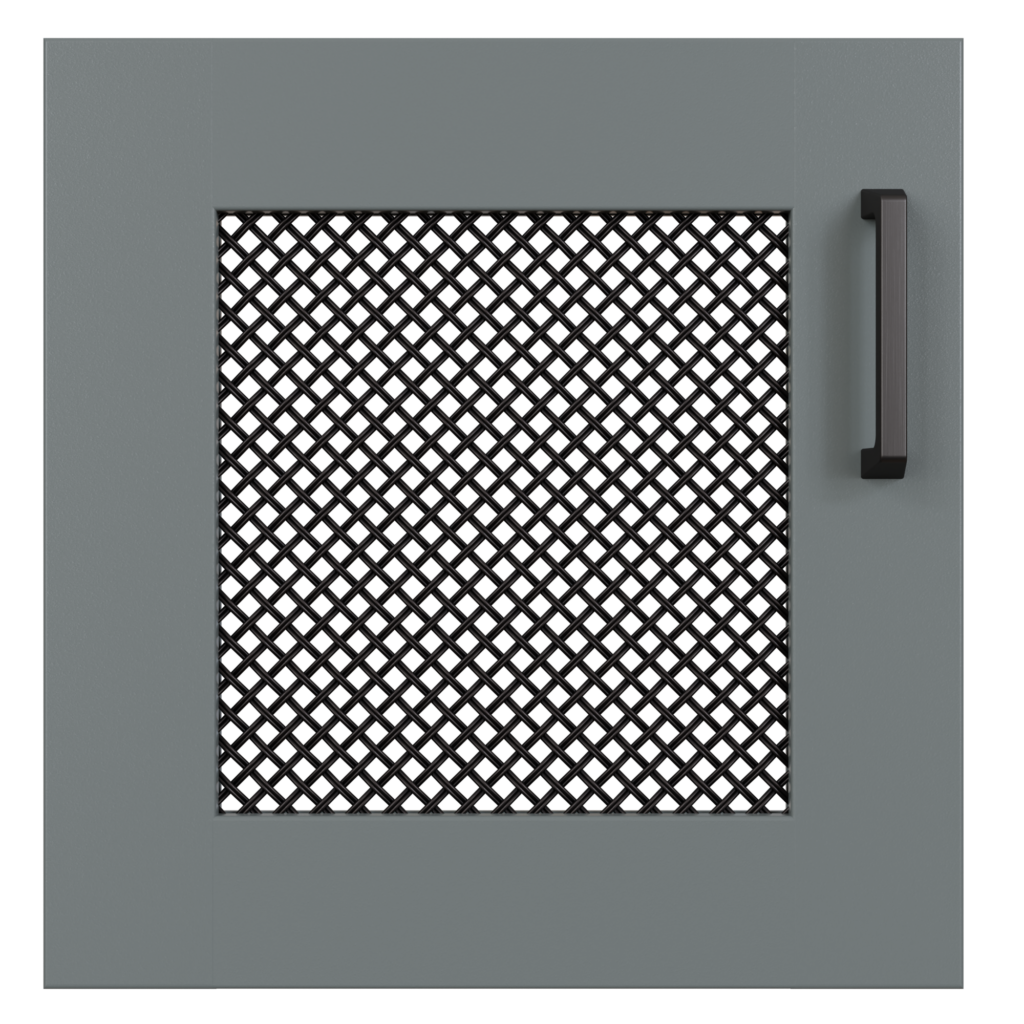

Product FAQ – Decorative Grilles & Mesh

Decorative Grilles & Mesh are finely woven by hand like a metal textile from steel wires. Decorative Grille offers an elegant alternative to glass in cabinet & furniture design. Choose from 11 styles of USA-made Decorative Grilles in 7 antique or bright finishes. In addition, we carry 5 styles of Italian-made Mesh. All styles are available in Stainless Steel, and Chevron Style #107 is available in Stainless Steel & Satin Brass.

NOTE: We offer several different styles of Decorative Grille and Mesh. We categorize each “type” as follows:

- Decorative Grilles refers to our USA-made grilles. USA-made grilles are finished through the electroplating process, hand woven and crimped from steel wires. Styles include: RE25, 315C, CG10, 1214F, 1220T, 286S, 332P, 11614P, and DK08.

- Fine Wire Mesh refers to style MESH. This mesh can be used in its own, but is typically used behind Decorative Grille for a layered look.

- Italian Mesh refers to Italian-made mesh styles including 107, 116, 118, 104, and 112.

- Other materials are categorized as “Cut-to-Size” Materials – including leather, resin, and rattan.

Where can I find Decorative Grilles & Mesh in your 2023 Product Catalog? Decorative Grille & Mesh styles are on pages 14-17 of the 2023 Product Catalog. You can view the Decorative Grille & Mesh pages here.

What are Decorative Grilles & Mesh used for? Decorative Grilles & Mesh are used for a variety of applications. Most of the time, Grille & Mesh panels are used as an alternative to glass in cabinet and furniture design to conceal what’s inside, as well as provide air flow.

Are Decorative Grille panels welded together? No, the wires are not welded together. Wires will separate if not handled with extreme care. This applies to all Decorative Grille & Mesh, including Italian Mesh.

What material is used to make Decorative Grilles? Grilles & mesh are made from steel wires, woven and crimped together like a metal textile on a loom. Wires are of different gauges, depending on the style.

How do I clean Decorative Grille panels? Wipe clean with any non-ammonia based cleaner. For best results, regularly dust clean, and wipe down with non-ammonia cleaner occasionally.

How do I order Decorative Grilles & Mesh? There are two ways to order Decorative Grilles & Mesh: by the sheet or cut-to-size based on your specifications.

- To order by the sheet or half sheet, simply select the size and finish on the product page and add to cart. Proceed to checkout and submit your order.

- Cut-to-Size:

- Order how many sheets you think you’ll need and select a finish

- Add to cart and proceed to checkout

- In the “order notes” section, type in your panel sizes and quantity

- We’ll double-check the math and ensure you are only charged for how many sheets your order will use, and email you with an order confirmation including pricing and panel sizes

- Please note that custom cut product, including cut-to-size panels, are not returnable.

What does “Cut-to-Size” mean? Cut-to-Size means that we will cut panels to your specifications so they are ready to install on-site upon delivery. Since Decorative Grille & Mesh panels are not welded, it can be extremely difficult to work with on-site. Our Cut-to-Size program reduces the chances of ruining expensive product on the job site.

How do you calculate pricing for Cut-to-Size Decorative Grille & Mesh panels? We’ve created an internal calculator tool to figure square feet and pricing according to your panel sizes. This calculator tool allows us to quickly identify how many square feet you’ll need for your project and price accordingly. We plan to roll out the square foot pricing calculator for customers in the coming months. In the meantime, please contact us through live chat, email orders@brownwoodinc.com, or call us at 800-328-5858 to calculate your square feet needs and price.

What size are the Decorative Grille panels? Decorative Grille, Fine Wire Mesh, and Italian-made Mesh dimensions are as follows:

- Decorative Grille – including styles RE25, 315C, CG10, 1214F, 1220T, 286S, 332P, 11614P, and DK08:

- Full sheet: 36″W x 48″L or 24″W x 72″L

- Half sheet: 18″W x 48″L or 36″W x 24″L

- Fine Wire Mesh:

- Full sheet: 41″L x 48″W

- Half sheet: 20″L x 48″W

- Italian Mesh including styles 107, 116, 118, 104, and 112:

- Full sheet: 59″W x 36″L

What finishes are available for Decorative Grille & Mesh? Finishes are as follows:

- Decorative Grille – styles RE25, 315C, CG10, 1214F, 286S, 332P, 11614P, and DK08: Antique Brass, Antique Copper, Antique Pewter, Satin Brass, Bright Satin Nickel, Stainless “Look,” and Flat Black.

- Decorative Grille style 1220T: Antique Brass, Antique Pewter, and Flat Black

- Fine Wire Mesh: Satin Brass, Bright Satin Nickel, and Flat Black

- Italian Mesh – styles 116, 118, 104, and 112: Stainless Steel

- Italian Mesh style 107: Stainless Steel and Satin Brass

How are the Decorative Grille finishes created? Both bright and antique finishes are created through a process called electroplating. Electroplating deposits metal finishes onto the steel through electricity. Finishes can vary from run to run.

How many square feet is each sheet? Square feet per sheet is as follows:

- 36″W x 48″L or 24″W x 72″L panels: 12 SQ feet

- 18″W x 48″L or 36″W x 24″L panels: 6 SQ feet

- Fine Wire Mesh – 41″L x 48″W: 13.67 SQ feet

- Italian Mesh – 59″W x 36″L: 14.75 SQ feet

How do I determine how many square feet of Decorative Grille I need? Multiply the width in inches by the length/height in inches, then divide by 144. For example, 18″W x 24″L would be (18*24/144) 3 SQ feet.

What if I need a sheet bigger than 36″W x 48″L? We will gladly create a custom quote for panels that are larger than our stock sizes.

How can I customize the Decorative Grille, Fine Wire Mesh, or Italian Mesh panels? Custom styles, finishes, and sizes are available and quoted upon request.

- Finish: Custom finishes include Bright Brass, Bright Chrome, Light Antique Brass, Bronze, Gold, Satin Copper, and more.

- Style: Contact us to see styles that we do not currently stock, but can quote upon request.

- Panel size: Panels larger than 36″W x 48″L or 24″W x 72″L available upon request.

- Please note: Currently, we do not offer customization of Italian Mesh finishes. However, Italian Mesh panel sizes beyond 59″W x 36″H are available upon request.

- Lead time: Typically, 4-6 weeks for custom styles and finishes.

How do I install Decorative Grilles & Mesh? We offer a Grille Retainer that’s designed to help securely install panels of decorative grille to cabinetry and furniture. This retainer removes the need for any additional fasteners and allows for easy adjusting or removal. Instructions to install Grille and Mesh panels using the Grille Retainer coming soon.

I need to show my client Grille Styles & Finishes. Do you have sample kits? Yes! We have a sample kit for Decorative Grilles & Mesh which includes all styles of our USA-made grilles and Italian Mesh samples. We also have a separate kit including only Italian Mesh samples. Contact us via live chat, email orders@brownwoodinc.com, or call us at 800-328-5858 to request a custom Decorative Grille & Mesh Sample Kit.

Have a question about Decorative Grilles & Mesh that isn’t answered above? Contact us through live chat at the bottom right of your screen, or fill out this form. We invite your feedback!

Product FAQ – Aluminum Components

Made in the USA, our Anodized Aluminum Components line includes Metallic Trim, L-Channels, Sleeves, Ferrules, and more. Due to the anodized finish, aluminum components will not chip, peel, rust, or corrode. In addition, finishes perfectly match; a Brushed Aluminum sleeve will match a Brushed Aluminum piece of trim. We carry 7 stock finishes ranging from deep flat black to bright polished brass.

Where can I find Aluminum Components in your 2023 Product Catalog? Metallic Trim can be found on pages 11-12. Sleeves and Ferrules can be found on page 49. View the 2023 Product Catalog here.

What components are made from Anodized Aluminum? Our Metallic Accent Trim, column sleeves, and furniture feet ferrules are USA-made from anodized aluminum. Details about each category of components below:

- Metallic Accent Trim includes our decorative aluminum bars, straps, and channels.

- Designer DripEdge™

- Column Sleeves includes sleeves designed to fit our 2″, 3″, 4″, and 5″ columns.

- Furniture Feet Ferrules designed to fit our square and round tapered feet and legs.

- Toe Kick Feet w/Metal Sleeve includes our 4.5″H feet with metal sleeve.

- Column sleeves, furniture feet ferrules, toe kick feet w/metal sleeve, and other metal furniture components can be found here.

- New Aluminum accents and finishes are added regularly. Subscribe to our newsletter to receive updates on new products.

What does “anodizing” or “anodized aluminum” mean? Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

- Anodized finishes are not applied like paint or plating – finishes are fully integrated into the aluminum substrate, so it cannot chip or peel.

- Anodizing is accomplished by immersing aluminum into a “bath” with a cathode to complete the oxidation process and create the finish.

- Anodizing is environmentally friendly, too! Anodizing does not generate hazardous waste or EPA-listed toxins.

- Anodized aluminum components are easy to clean with any non-ammonia based cleaner.

- Due to anodized finishes – aluminum components perfectly match each other. For example, a Polished Brass L-Channel will match a Polished Brass Strap.

What finishes are available for Aluminum Components? Finishes are as follows:

- Metallic Trim – Brushed Aluminum, Chrome, Flat Black, Satin Brass, Polished Brass, Warm Bronze, and Satin Stainless

- Designer DripEdge™ – Satin Brass, Brushed Aluminum, and Flat Black

- Column Sleeves – Brushed Aluminum, Chrome, Flat Black, Satin Brass, Polished Brass, Warm Bronze, Satin Stainless, and Soft Gold

- Furniture Feet Ferrules – Brushed Aluminum, Chrome, Flat Black, Warm Bronze, and Satin Brass

- Toe Kick Feet – Brushed Aluminum, Chrome, Flat Black, Satin Brass, Polished Brass, Warm Bronze, and Satin Stainless

How can I customize Aluminum Components? Customization for Aluminum Components available for finish and size. Please note required MOQs may apply, and allow 4-6 weeks for custom Aluminum Components. Contact us to get your custom quote started today.

How do I install Aluminum Components? Please see below for installation tips:

- Metallic Trim – we carry a strong, double-sided, clear industrial UHB tape that’s temperature and moisture resistant to adhere to mouldings and cabinet panels.

- Column Sleeves and Ferrules – We dado columns and feet so that the aluminum sleeve slides seamlessly onto the bottom of the leg. Attach sleeves and ferrules to legs with UHB tape or other adhesive.

- Designer DripEdge™ – includes pre-applied UHB tape, no additional adhesives are necessary.

What are the part numbers for Columns with Sleeves? Dadoed Columns with Sleeves are sold as a kit! Columns with sleeves are located in the Posts, Columns, & Table Legs section of our catalog. We stock 2″, 3″, 4″ and 5″ pre-cut columns for a flush fit with the aluminum sleeve. We also carry pre-cut columns with a 4.5″H sleeve (toe kick height).

Have a question about Aluminum Components that isn’t answered above? Contact us through live chat at the bottom right of your screen, or fill out this form. We invite your feedback!

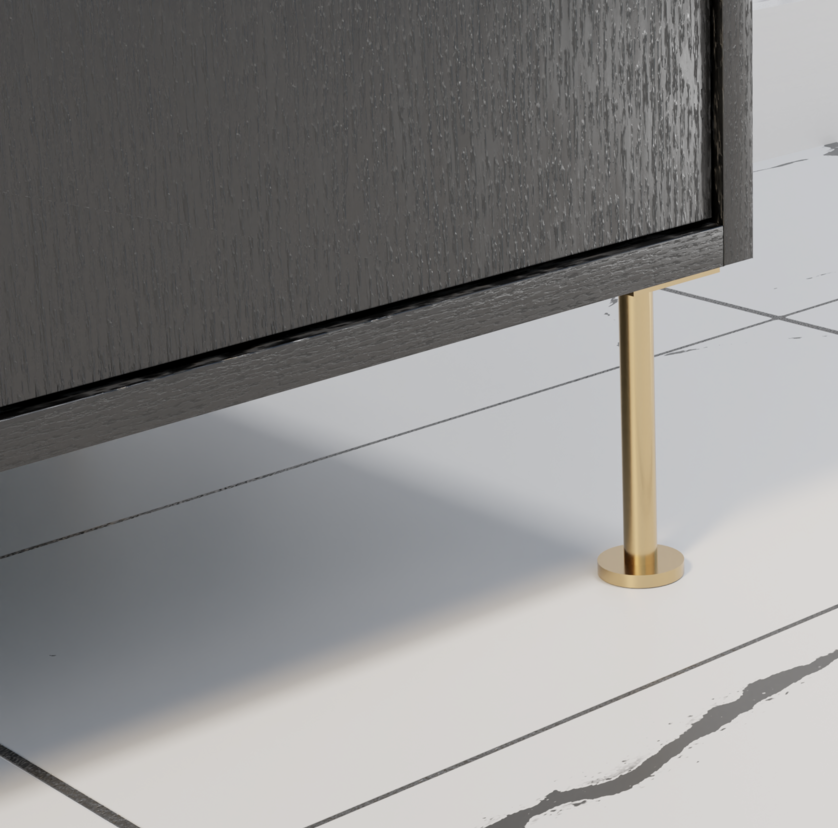

Product FAQ – Brass Components

Our new line of Solid Brass Components feature the finest quality cast brass. Cast brass, made of a copper/zinc alloy, is known for its material integrity, smooth surface finish, durability, and strength. Cast brass components will outlast normal wear and will maintain its bright finish for years to come.

In this section, you will find FAQ for our Decorative Brass Hardware, Slipper Cups, Furniture Feet, and Gallery Rail.

*Please note: this section does NOT include Brass Bistro Shelving FAQ. Brass Bistro Shelving FAQ coming soon!

Where can I find Brass Components in your 2023 Product Catalog? We carry decorative brass hardware and straps, slipper cups, furniture feet, and gallery rail. Decorative brass hardware can be found on page 13. Solid brass furniture feet are on page 50, and slipper cups are on page 51. Gallery rail can be found on page 85.

What Brass Components do you stock? Please see below for a detailed list of our stock Brass Components:

- Decorative Brass Hardware and Straps: Design possibilities with our Decorative Brass Hardware and Straps are endless! Frame cabinetry and drawers with our brass accents, found on page 13 of our 2023 Product Catalog.

- Slipper Cups: Designed to slide over legs and feet, Slipper Cups include installation hardware to screw into the bottom of the leg. Find our selection of Slipper Cups on page 51 of our 2023 Product Catalog.

- Furniture Feet: Solid Brass Furniture Feet can be installed by directly screwing the leg into the frame of furniture, cabinets, vanities, and more, and can be found on page 50 of our 2023 Product Catalog.

- Gallery Rail: We’ve added new finishes and styles of Brass Gallery Rail, including flat black, polished chrome, and stainless steel. Gallery Rail components can be found on page 85 of our 2023 Product Catalog.

Brass Strapping & Decorative Hardware

Our Decorative Brass Strapping offers an easy way to add a splash of brass to your designs. The flat brass bars are .375”W x 48”L and can be cut on-site to fit your specifications. Combine with our decorative corner straps to finish the look.

Flat brass bar: 01HC1007PB1

Brass corner strap: 01HC1006PB1

How do I install the .375″ Brass Strap? The .375″ Brass Strap (01HC1007PB1) can be installed using our strong, double-sided, clear industrial UHB tape that’s temperature and moisture resistant to adhere to cabinets, furniture, and more.

How do I install the .375″ Brass Corner Strap? The .375″ Brass Corner Strap (01HC1006PB1) includes matching screws to install directly onto cabinets, furniture, and more.

Can I cut Brass Straps on-site? Yes. Since Brass is a relatively “soft” metal, it can be cut on-site using a non-ferrous, high tooth count, carbide blade that’s designed for metal. We also recommend using a saw lubricant/oil to reduce metal-to-metal friction.

I don’t want to cut on-site. Can you trim the straps for me? Yes. Add the component to your cart and proceed to checkout. In the “order notes” section, let us know your specifications. A cut fee will apply. Please note that custom cut product is not returnable.

How can I customize Decorative Brass Hardware? See below:

- Finish: Custom finishes include antique brass, oil rubbed bronze, copper, flat black, and more. Please be advised that custom finishes for brass components can be expensive, and custom product cannot be returned.

- Length: Brass strap length can be customized by either having us cut down or trimming on-site.

- Further customization may be available. Contact us with your custom requests using the live chat at the bottom right of your screen, emailing orders@brownwoodinc.com, filling out the form at the bottom of this page, or calling our office at 800-328-5858.

I need to show my client the Decorative Brass Hardware. Do you have sample kits? Yes, we have a variety of sample kits with these components. See below:

- We have a sample kit for the .375″ Brass Strap and .375″ Corner Strap – 01375STRAPKIT.

- Our Metal Trim Sample Kit (01METALTRIM) includes samples of 01HC1007PB1 and 01HC1006PB1, as well as samples of each metal (aluminum) trim profile we carry.

- Our new Mini Materials Box (01MINIMATKIT) includes samples of 01HC1007PB1 and 01HC1006PB1, as well as samples of 4 Tambour profiles and 3 Decorative Grille & Mesh designs.

- The Full Sample Kit (01SAMPLEBOX22A) includes Decorative Brass Hardware samples, along with other sample components and materials.

Brass Feet & Slipper Cups

We’ve recently added several styles of Solid Brass Furniture Feet and Slipper Cups, ranging from eclectic to contemporary. Imported from the UK, our Brass Furniture Feet and Slipper Cups are one-of-a-kind.

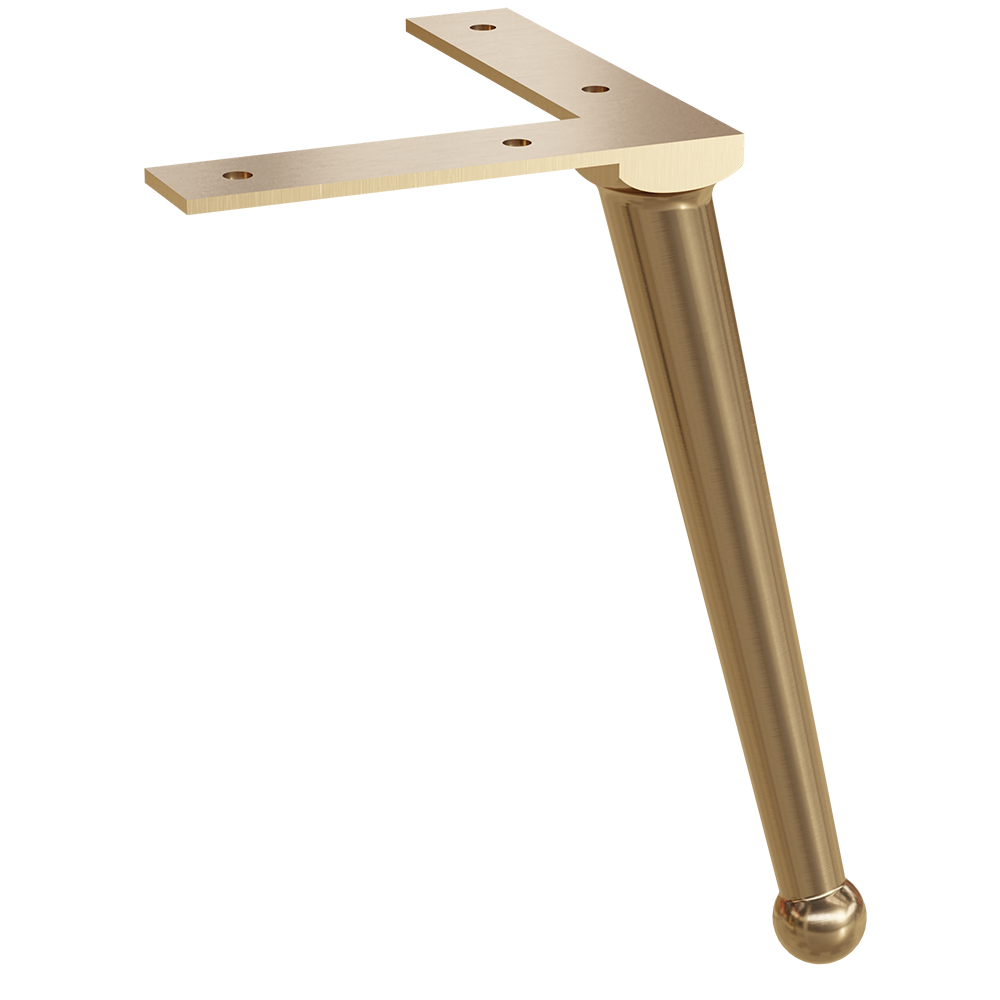

Featured: Tyne Leg (01700410PB1)

What styles of Brass Furniture Feet do you carry? We currently stock 4 styles of Solid Brass Furniture Feet. See below for the 4 Solid Brass Furniture Feet options we stock:

From left to right: Tyne (01700410PB1), Essex (01700412PB1), Devon (01700406-1), and Rutland (01700408-1)

Where can I find Brass Furniture Feet in your 2023 Product Catalog? Brass Furniture Feet can be found on page 50 of our 2023 Product Catalog. Additionally, you can find Brass Furniture Feet here.

What styles of Slipper Cups do you carry? We have a selection of square tapered, round tapered, and round slipper cups in a variety of finishes. Round/Short Slipper Cups (01SLPR101-1 and 01SLPR103-1), Square Tapered Slipper Cups (01SLPR107-1 and 01SLPR106-1), and Round Tapered Slipper Cups (01SLPR105-1 and 01SLPR104-1).

Left to right: Round Slipper Cups, Square Tapered Slipper Cups, Round Tapered Slipper Cups

Where can I find Brass Slipper Cups in your 2023 Product Catalog? Brass Slipper Cups are featured on page 51 of our 2023 Product Catalog. Additionally, you can find Slipper Cups here.

Are your Brass Furniture Feet and Slipper Cups actually made of Brass? Yes. Our Solid Brass Furniture Feet and Slipper Cups are made of solid polished and lacquered brass.

How do I install Solid Brass Furniture Feet and Slipper Cups? Solid Brass Furniture Feet include matching hardware to screw directly into the furniture frame through the screw holes on the top of the legs. Slipper Cups include hardware to screw into the bottom of the leg.

How can I customize Brass Furniture Feet and Slipper Cups? Currently, the only customization that can be made is finish. Custom finishes include antique brass, oil rubbed bronze, copper, flat black, and more. Please be advised that custom finishes for brass components can be expensive, and custom product cannot be returned.

Do you plan on adding more Brass Furniture Feet and Slipper Cup styles? We plan on expanding our line of Brass Furniture Feet and other brass components as new trends emerge. Contact us to see Brass Furniture Feet styles we do not currently stock, but can quote upon request.

I need to show my client Brass Furniture Feet and/or Slipper Cups. Do you have sample kits? Currently, we do not have a sample kit with Brass Furniture Feet. However, we do have a sample kit for Brass finishes (01BISTROKIT).

Gallery Rail

Now available in 5 finishes and 2 styles – traditional polished brass, satin brass, chrome, flat black, and contemporary stainless steel. Attach Gallery Rail components to the tops of cabinets, furniture, shelving and more to make use of typically unused space. Create an eye-catching, luxury look by installing a Gallery Rail to provide added stability, outline the perimeter of desks, bookcases, and shelving, or on the tops of cabinets.

Featured: Traditional Gallery Rail Components in Polished Brass

Where can I find Gallery Rail Components in your 2023 Product Catalog? Gallery Rail Components can be found on page 85 of our 2023 Product Catalog.

How is the Gallery Rail typically used? Gallery Rail can be used to provide added stability to shelving, as well as outline the perimeter of desks, bookcases, and tops of cabinets. Showcase antiques, barware, dinnerware, artwork, and more using the Gallery Rail. Additionally, the Gallery Rail can be used to hang cooking utensils, dish cloths, and more. The design opportunities are as endless as your imagination!

What do I need to create a Gallery Rail? Please see below for our recommendations.

- To begin, measure the area where you plan to install Gallery Rail. Measure across the front and along the sides, if you plan on extending the Gallery Rail around corners.

- Order your components – be sure to include corner posts if needed. Other components you’ll need include:

- Center Post – used to connect rail across the center (01HC9001-1)

- Corner Post – used to create 90-degree corners (01HC9002-1)

- End Post – used at the end of Gallery Rail (01HC9003-1)

- Rail – 36″L solid brass gallery rail (01HC900436-1)

How do I install Gallery Rail Components? Screw center posts into furniture, shelving, and more with the included matching installation hardware. Slide the gallery rail into the posts; trim the rail if necessary using a non-ferrous, high tooth count, carbide blade that’s designed for metal. Then, install the corner and end posts to complete the Gallery Rail. Typical spacing between posts across the front is approximately 6″ – 10″ apart.

What finishes are available for Gallery Rail? Our traditional Gallery Rail components are offered in Polished Brass, Satin Brass, Flat Black, and Chrome. We carry Contemporary Gallery Rail components in Stainless Steel.

I need to show my client Gallery Rail components. Do you have sample kits? Yes! We have a number of sample kits that include Gallery Rail components:

- Full Sample Kit contains posts and rods in all 5 colors – Polished Brass, Satin Brass, Chrome, Flat Black, and Stainless Steel (01SAMPLEBOX22A)

- 10 Piece Gallery Rail Sample Kit includes one sample rod and post for 01HC9003-1 and 01HC9004-1 in each of the finishes we offer (01GALLERYRLMINI)

- 20 Piece Gallery Rail Sample Kit includes one sample rod in each finish, and a corner, center, and end post in each finish (01GALLERYRLSET)

- 4 Piece Contemporary Gallery Rail Kit includes one of each Contemporary Gallery Rail component in stainless steel: end post, center post, corner adapter, and 12″ sample rod (01GALLERYRAILSS)

- 4 Piece Chrome Gallery Rail Kit includes one of each Gallery Rail component in Chrome (01GALLERYRAILCR)

- 4 Piece Polished Brass Gallery Rail Kit includes one of each Gallery Rail component in Polished Brass (01GALLERYRAILPB)

- 4 Piece Satin Brass Gallery Rail Kit includes one of each Gallery Rail component in Satin Brass (01GALLERYRAILSB)

- 4 Piece Flat Black Gallery Rail Kit includes one of each Gallery Rail component in Flat Black (01GALLERYRAILWR)

Have a question about Brass Components that isn’t answered above? Contact us through live chat at the bottom right of your screen, or fill out this form. We invite your feedback!

FAQ for Bistro Shelving, Shelving, X-Panels, Sample Kits, and more coming soon! Stay up-to-date on the latest information from Designs of Distinction by subscribing to our newsletter.

Please note that Our FAQ page is under construction! Check back regularly for FAQ updates.

Have additional questions? Please live-chat us below, contact us here, or submit your question through this form.