Cabinet Manufacturers Association’s (CMA) publication, PROfiles, is a quarterly magazine focused on member’s achievements, business practices, innovative projects, and more. Their Fall 2023 issue features Designs of Distinction as a Featured Associate; Kathy Constantine, VP of Designs of Distinction, had the opportunity to interview with Carla Atkinson from CMA. We’re excited to share the “Partners in Style” interview!

CMA PROfiles Fall 2023

“Partners in Style” Intro: Overview of BWI History & Introduction to Kathy Constantine

CMA introduces Designs of Distinction at the outset of the article, providing a comprehensive and accurate portrayal of our parent company Brown Wood, Inc., which began in 1927 by George Brown.

1927: Brown Wood Products Begins

Brown recognized that original equipment manufacturers (OEMs) in the Midwest didn’t have a source for quality wood components. He sought to provide wood turnings for tools – like garden tools – but soon realized that the military and agricultural industry needed wood bearings and/or fully machined parts.

By the early 1950s, Brown’s business grew into a full-service company, “providing wood parts and components for virtually every conceivable need for diverse markets across the United States,” CMA writes.

Today, Brown Wood, Inc. (BWI) has multiple divisions and brands – Made-to-Spec® (MTS) and Designs of Distinction® (DOD) being two of them.

Made-to-Spec & Designs of Distinction are 2 divisions of Brown Wood, Inc.

“Partners in Style” Intro: Kathy Constantine, Vice President

Kathryn (Kathy) Constantine joined BWI in the late 1980s, filling various customer service and sales roles. In 1998, 10 years after joining BWI, Constantine established a new brand – Designs of Distinction (DOD) – which focused on decorative wood components for Kitchen & Bath. Today, DOD’s stock product offering has expanded to offer more than just wood components for kitchen & bath – metallic accents, structural wood and metal supports, shelving, and more – for residential and commercial spaces.

Constantine’s Accomplishments & Inspiration

CMA highlights some of Constantine’s accomplishments as Vice President of BWI, noting how she’s created “both large and small spec book programs for various manufacturers, developed new products that answer current design trends, and expanded Designs of Distinction’s components beyond the traditional wood products.”

The “Partners in Style” interview focused on the latest design trends and how Constantine finds inspiration in small custom cabinet makers.

“Partners in Style” – The Interview

Carla Atkinson of CMA interviewed Constantine in thorough detail. The full article is available on CMA’s PROfiles online archives. We’ve paraphrased and summarized some of Constantine’s responses below.

How did Designs of Distinction get its start?

I joined BWI in 1989 and at first worked in customer service. In the mid-1990s, I noticed tables in different heights and styles at stores like Macy’s with merchandise – folded sweaters, for example. I thought, “what a idea! Let’s make stock table legs for this market.” With that inspiration, I created 15 different designs… and nobody bought them! But I did have a cabinet maker call and say, “I really like that leg. Can you make it taller and fatter? I want to use it in a kitchen on an island.” And that’s how we got started!

Designs of Distinction Web Banner from 2006

The Designs of Distinction division was officially launched in 1998, starting with a line of stock columns for the kitchen & bath market. At first, our customers thought we were making newel posts for stair parts, but soon realized that kitchen islands as furniture pieces were becoming increasingly popular. As kitchens became more of a showpiece and central to the home, we found that carvings, mouldings, and bun feet were in demand along with columns. Eventually, the line grew.

We added carved corbels, onlays, tiles, and mouldings to meet the demands of the ‘new’ market. I like to say that we take a box and make it look like furniture. We don’t make the box – we make the stuff that makes it look like furniture.

Fast forward from those early days, and we now supply many of the largest OEM manufacturers as well as small, custom bespoke manufacturers.

Just before COVID, we started to see that trends had changed. Shaker style became the world, with white kitchens that had no ornamentation. We had to pivot – but pivoting is something we do pretty well. Brown Wood has a custom division called Made-to-Spec, and many of its clients are small cabinet manufacturers who do custom work and are on the forefront of new design much more than big OEMs. These cabinet makers ask us to make custom parts, and that helps Designs of Distinction spot trends and pivot as needed.

Custom Leg Quoted & Manufactured by our Made-to-Spec division.

Can you talk about the trends that have been driving your product decisions in recent years, starting with that pivot you had to make just ahead of COVID?

We started to see metal and mixed materials coming forward just before COVID, so we added metallic trim to our offerings, and that’s taken off for us. We’re seeing a lot of soft brass and gold colors, adding a bit of warmth to the white kitchen. I think people were getting sick of the cold, clinical white Shaker look that had dominated kitchen design for so many years. However, they did like it’s simple form, so we needed to figure out how to fit into this new design aesthetic. The question became, “How can you enhance things a little without going all the way back to acanthus leaves on everything?”

It’s also become okay to mix metals. There was a time when everyone thought, “Oh, my knob needs to match my faucet, which needs to match my hinge.” That’s not the case anymore. It’s perfectly acceptable to have stainless steel and flat black and bronze all in the same kitchen. That was helpful for us because it’s virtually impossible to create a finish that matches everyone else’s hardware when it comes to our metallic accent line.

As for other trends, I get a lot of information from walking trade shows in other industries – the International Contemporary Furniture Fair and Boutique Design New York, for instance. This past spring, I walked the High Point Market, and what was really shocking was the lack of color. Taupe, white, brown, and black were everywhere. If there was color, it was in wallpaper, linens, and some carpeting.

The other design element I noticed was the use of texture – fabrics like boucle, smooth leather, cool metals, textured walls, for example. These textured walls were not rough shiplap or heavy textured surfaces, they were wood tiles in geometric patterns, textured panels, and tambour. The materials used on upholstery were softer and more subtle. Wall treatments and hard goods were made from materials that projected warmth, such as grainy white oak and walnut.

Pieces from High Point Market

At High Point, the message was that if you wanted color, you just wanted a pop of color, through wallpaper in prints and patterns or gorgeous bedding and towels. Furniture, hard goods, and tables were textured – you weren’t going to see a clear maple dresser that was smooth and had no grain pattern. If wood was being used, it was grainy woods like white oak and ash. You could mix leather, black steel, boucle, and brass-tipped arms all on a countertop stool. It was really beautiful, though I’m not sure how practical it is!

What are your thoughts about COVID’s impact on design trends?

Well, of course, everyone stayed at home first. Those cold, white kitchens began to feel oppressive, and people thought if they couldn’t go out, they would bring the outdoors in. Enter the newest trend, known as Biophilic Design.

Enter the newest trend… Biophilic Design

Constantine states, “The idea took hold that bringing nature into your home was not just physically healthy but also mentally healthy. In all the shows I’ve walked this year, I can definitely say trends are very much tied to nature – texture, mixed materials, and tactile finishes.”

Because people got accustomed to staying at home, they began making their home a more comfortable space. Wood, one of the most prevalent materials in nature, is warm to the touch, visually pleasing, and easily transformed. More clients are integrating wood into their designs. I’m seeing more furniture-style islands and fewer waterfall islands; as a person whose company makes columns and legs, this makes me very happy!

Painted cabinetry and natural wood furniture-style island designed for seating.

Thankfully, natural wood finishes on cabinetry is making a comeback – it’s not just pure white painted finishes, people want to warm up that white kitchen. White and grey are still huge, but adding warmer accents makes the space feel more comfortable and homey. Painted uppers and natural-grain lowers are gaining traction along with nature-inspired colors like greens and blues.

One of our newest products is a line of Tambour panels for furniture and walls. We are seeing a lot of interest in these beaded and fluted panels, reminiscent of mid-century design, to warm up the kitchen.

Featuring: Island designed for seating with new base shape for use with Tambour (premiering at KBIS 2024).

The other idea that’s gaining in popularity is creating a healthy home. Consumers are seeking out antimicrobial materials in countertops, cabinets and flooring, and touchless faucets. The healthy home is definitely a trend worth watching.

How can cabinet makers best incorporate trendy materials?

The thing I love about the small cabinet maker versus the large OEM is the fact that they’re able to incorporate designs almost instantaneously. They can change their production or add color and design features pretty quickly, whereas OEMs could face a two-year process to get something added to their line; by that point, they’re already behind the times.

Trends used to come from Europe, and it would be two years before you’d see it come to the States. Trends would start on the Coasts and slowly move to the Midwest. That’s not the case anymore. With social media, trends are instantaneous and we have to be able to respond to that quickly.

The small cabinet maker is able to do that better than anyone. A lot of products we’ve added have been geared towards someone who can take an item and add it to an existing product or sell it as a pass-through item.

People are looking for simple details to enhance an area of the kitchen, creating a focal point. Coffee bars and wine bars, for example, and we have quite a few options for making those specialized cabinets stand out. We’re also seeing people create a focal point in the kitchen by using natural finished wood. Maybe you have blue cabinets, but your baking center is walnut with a different countertop. Our mesh and rattan is another way to differentiate an area by adding texture.

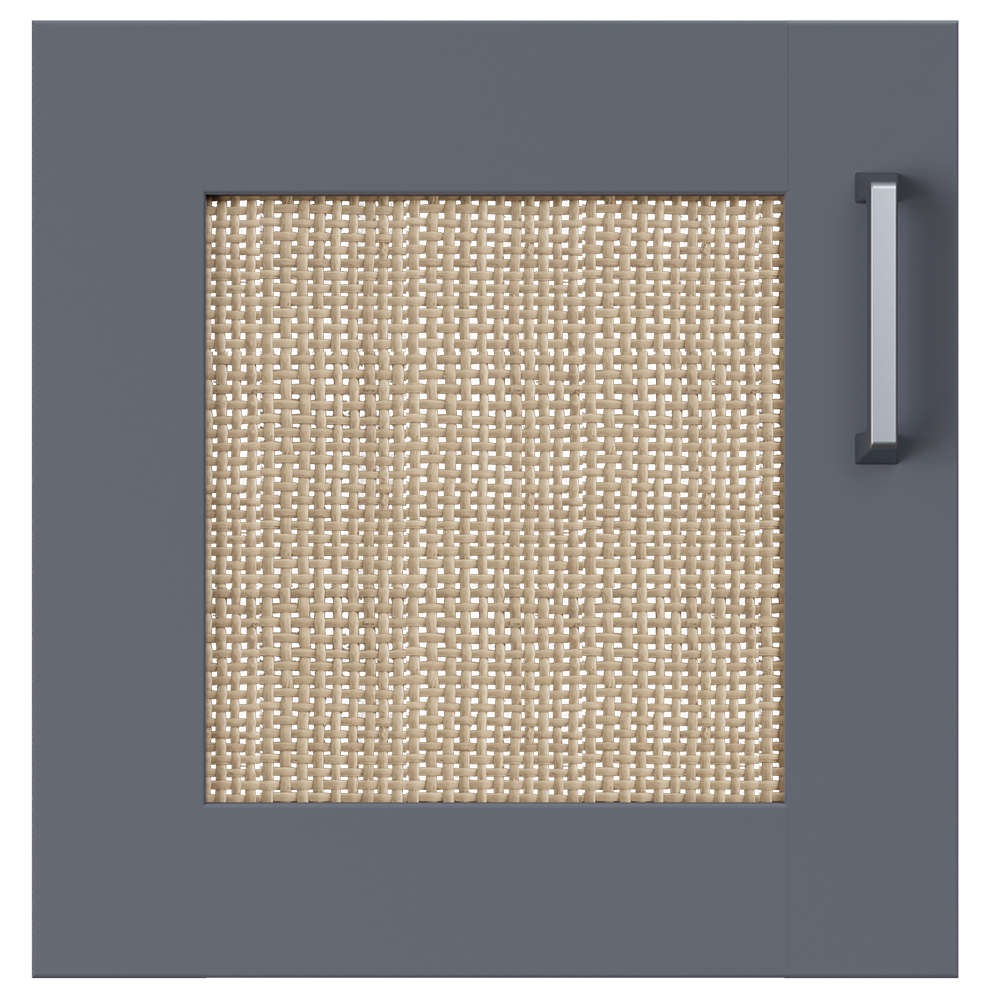

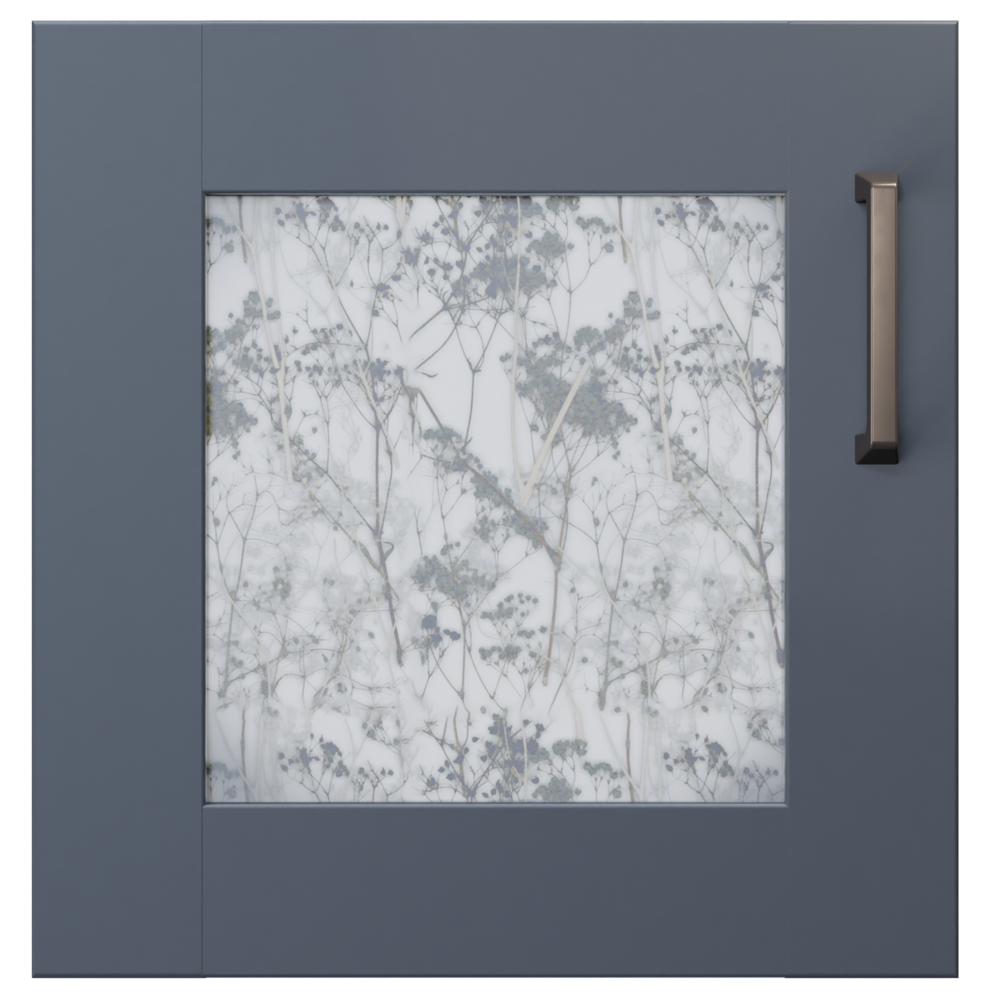

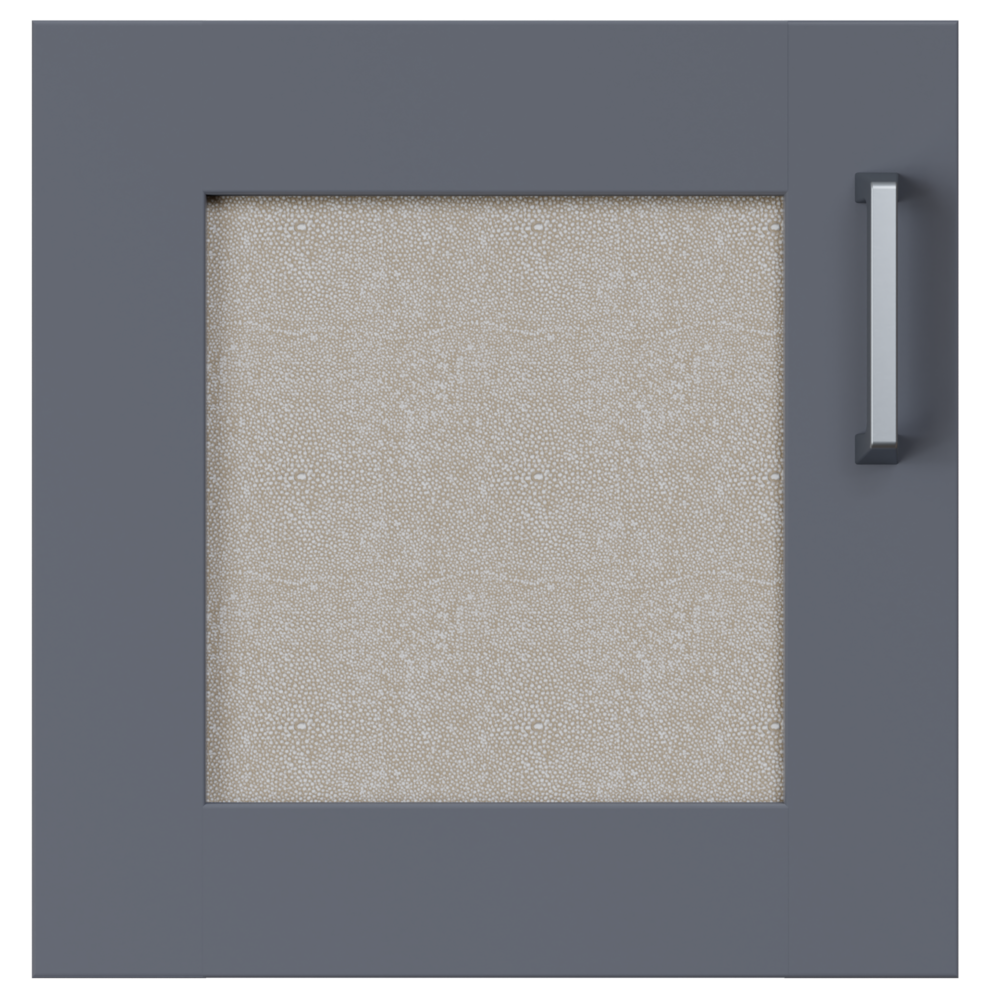

Left to right: Square Rattan, Botanical Resin, Pebbled Leather. See all Cut-to-Size Materials here.

Another great thing about custom cabinet makers is that they don’t have to change their production extensively to accommodate our new products. Our decorative grilles, mesh, and rattan are designed to fit into the standard route for glass, so if cabinet makers are already making doors cut for glass, our product goes in the same way. We cut it to size, you stick it in with a rubber gasket, and suddenly you have a completely different cabinet.

Our metallic trim is also easy to add to both the frame and the door of a cabinet with ultra-high bond tape. The newest product from our metallic trim line, the Designer DripEdge, which is designed to protect the top edge of garbage can pull-out cabinets; we now offer not only beauty, but function!

Designer DripEdge – Winner of the 2023 KBB Product Awards in the Functional Hardware category. Read the blog post here.

Your Cut-to-Size Materials Showroom Display frame is a clever, unique way to showcase the variety of styles and finishes you offer. How did this concept evolve from the traditional sample kit?

When we first developed the line, we had eight SKUs, and we would route out a frame for samples. But cabinet dealers began saying they wanted to showcase all the styles, and we had to come up with different size frames based on what the dealer would like to show to their customer. What I like about this display solution it that it shows the variety of options in a way it would be used functionally, allowing the consumer to say, “Oh, that’s what it would look like in my cabinet.”

Above: Cut-to-Size Materials Showroom Display Frame

Why does it make good business sense, especially for the smaller shops in the industry, to outsource components like the ones you provide?

First, it allows a tremendous amount of variety. They’re able to expand their offerings and meet almost any trend because they can just buy a component they don’t or can’t make. That makes them appear “bigger,” as it doesn’t make sense for them to invest in a setup to manufacture products like ours.

Efficiency & Variety

In today’s world, where labor is still an issue for our industry, outsourcing allows you to be efficient at what you do well, and still provide a lot of different styles to your customer base.

What does Designs of Distinction gain from its relationship with the CMA?

As I’ve mentioned, I find that product and trend developments come from smaller cabinet shop owners, especially if they do custom work. They are the ones who have clients who say, “I saw this in Architectural Digest. Can you modify it to make it fit in my kitchen?”

We pull from their ideas and learn from them – they were the first to come to us when we started to see white oak and walnut become hot again. That’s not coming from the large OEMs; the OEMs are following.

Above: Hardwood X-Panel

One example of this is our large X-panel. It’s manufactured using mortise and tenon and lap joint assembly. While it’s something cabinet makers can make, they usually don’t want to. That product was developed after a small cabinet business called us and asked us to make one, because it was too time-consuming for them to product. Ultimately, it became a product that we offer in our stock catalog and provide frequently on a custom basis.

We feel that the small cabinet maker is on the forefront of the trends, and that is huge for us.

About Us: Designs of Distinction, founded in 1998, began as a small supplier of furniture parts. Today, we work with the largest brands in the industry to develop new and innovative products for cabinetry and furniture.

From the moment the first cabinet maker called and asked us to make a leg that was “bigger and wider, to hold up a countertop,” to the day we introduced our first metal component in 2014, Designs of Distinction continues to lead the industry in the latest materials, finishes, and components for kitchen, bath, and furniture.

Custom components are our specialty – furniture components, store fixtures, or otherwise – Designs of Distinction can help you bring your next project to life.